EVOLVING with PURPOSE THROUGH CIRCULAR DESIGN

The Problem.

Waste is a growing concern on our planet, with the fashion industry being one of the major contributors. A significant factor contributing to this issue is the challenge of recycling due to the diverse materials used in each product.

Despite increasing support from regulations, brand commitments to sustainability, and shifts in consumer behavior, these efforts have not yet reached the scale needed to tackle global challenges like climate change and resource scarcity. As part of ZALANDO private label, We want to challenge this by promoting circularity on a larger scale and reaching a wider audience.

In Private Label, as part of the larger do.BETTER strategy, we want to transform the way products are designed by applying Circular Design criteria. Our goal is to offer a better range of products, focusing on innovation, durability, and recyclability potential, empowering our customers to make informed choices and be part of the movement.

The Objectives.

My Role.

In late 2022, we continued to expand our internal knowledge and advance our circular product offerings across our private-label brands.

With the support of my design colleagues, I spearheaded the development of capsule collections in our lighthouse footwear brand, “ZIGN Lighthouse.” We collaborated closely with my colleagues in design, product development, and materials. We curated collections that prioritize single-material footwear, showcasing innovative materials like Naia™, a biobased faux leather made from coffee grounds, recycled fishnet nylon, and other renewable and recycled materials. Additionally, the collections feature modular design elements where applicable, enhancing both versatility and product lifespan.

What I did.

Innovative Material Assessment

Stakeholder Engagement & Management

Modular Design Element Research

Collection Building

Tech Pack Creation

The Process.

1 . Supplier Base Selection

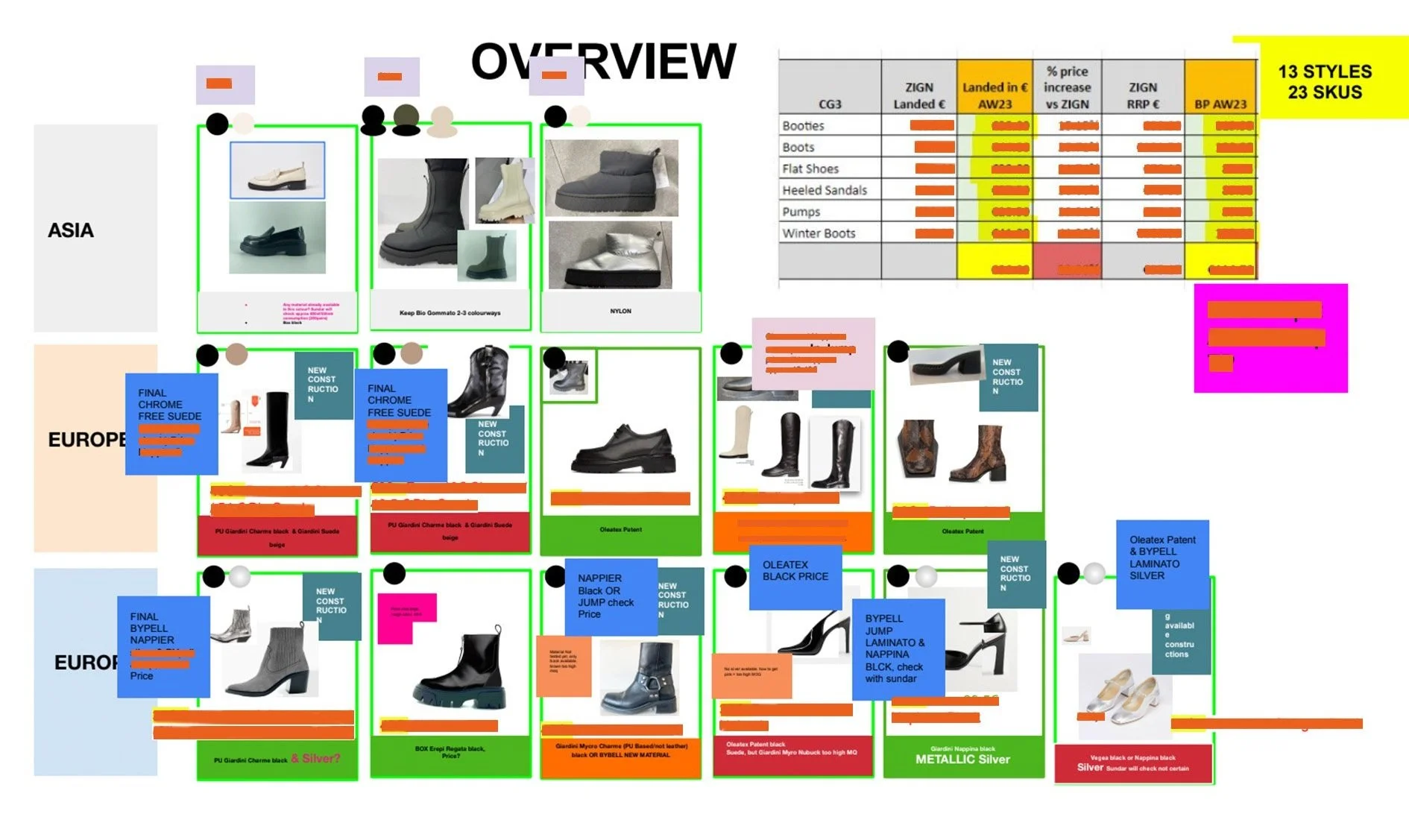

At the same time, we work closely with the product supply and material teams to nominate suppliers based on responsible sourcing guidelines and the availability of innovative materials in each region. We then allocate SKUs according to footwear category and intended launch month to ensure deadlines are met.

Observation

Creating circular footwear focusing on a single innovative material requires considering the broader supply chain. To reduce our carbon footprint, we prioritize manufacturing the footwear in the same region as the material supplier.

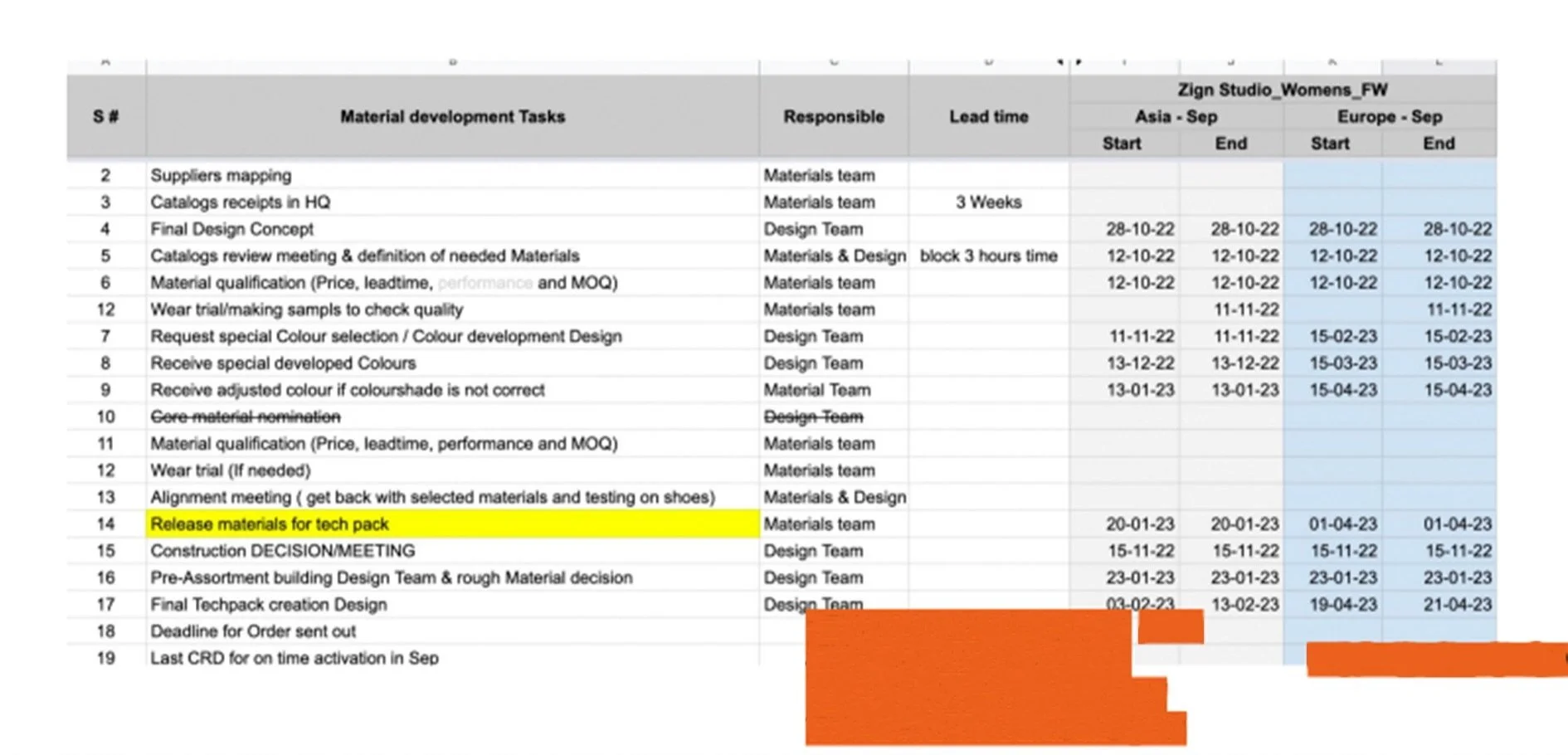

2 . Timeline Creation

'ZIGN STUDIO' is a Lighthouse project that requires timely involvement from various stakeholders to ensure the launch date is met. With my design lead as the key person, I provided essential support by creating a timeline in coordination with each stakeholder, ensuring that all key milestones are achievable and manageable.

Observation

Creating a scalable circular product truly requires teamwork to ensure it aligns with our vision and mission.

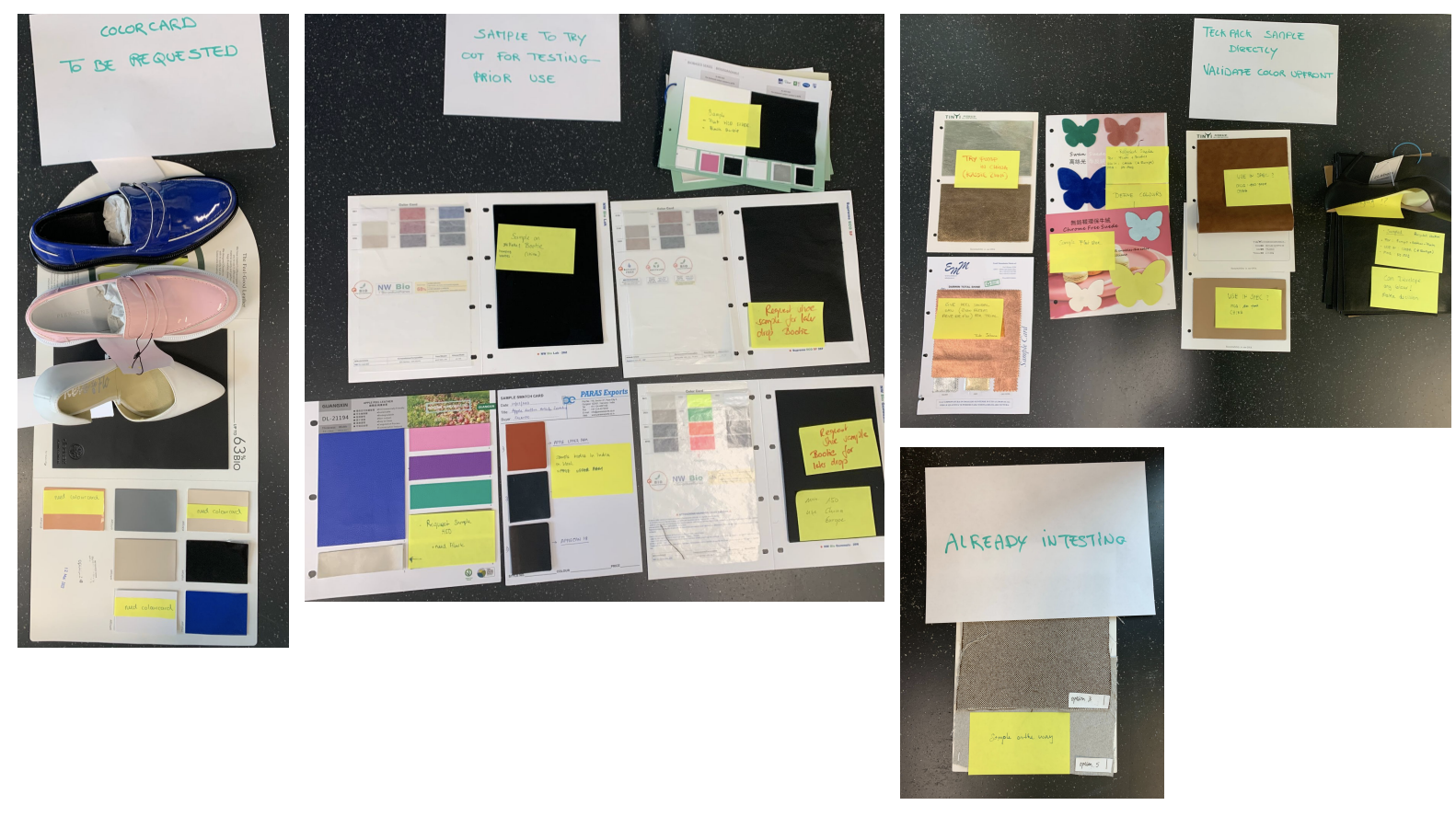

3 . Material Selection & Assignment

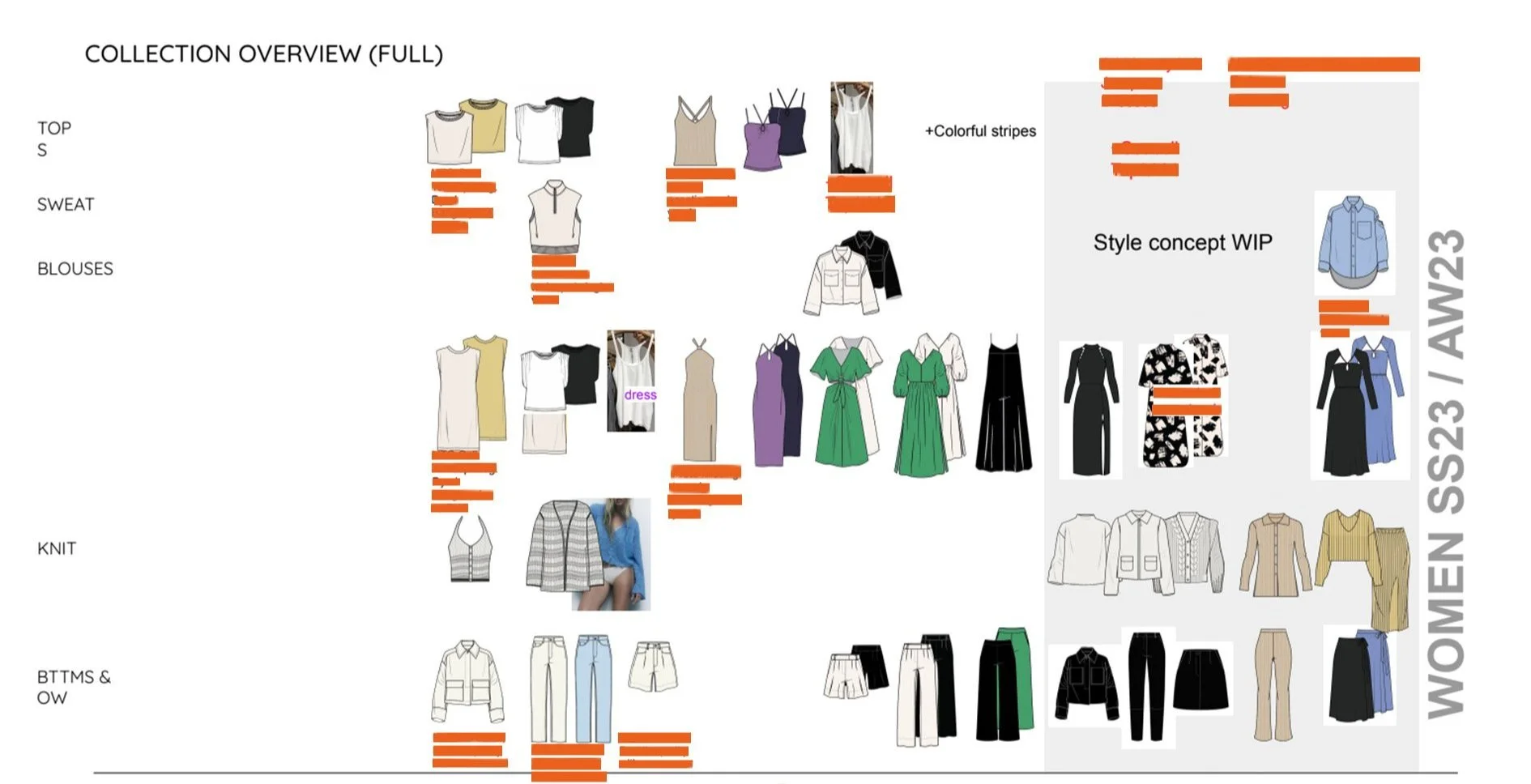

With the support of the Materials Team, the Design Team selected innovative materials focused on reducing the carbon footprint by choosing options within the nominated factory's region. As ZIGN STUDIO is a lighthouse brand offering a complete look to our customers, we also work closely with the Apparel Team on the color palette.

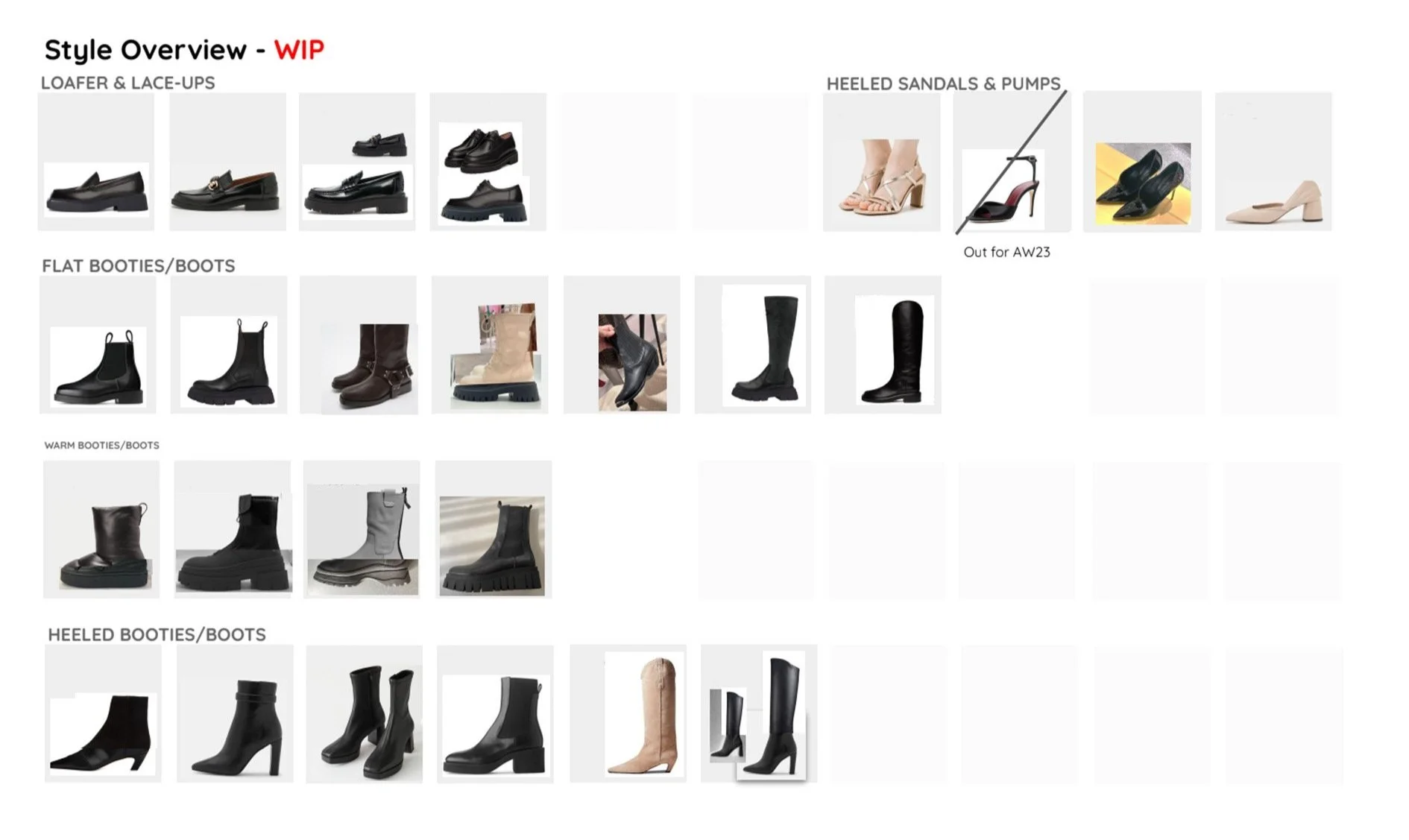

4 . Line Building

Leveraging our product design expertise, we strive to build a balanced collection that aligns with seasonal trends and price frameworks while addressing market demands for superior products through innovative materials.

5 . Tech Pack Creation

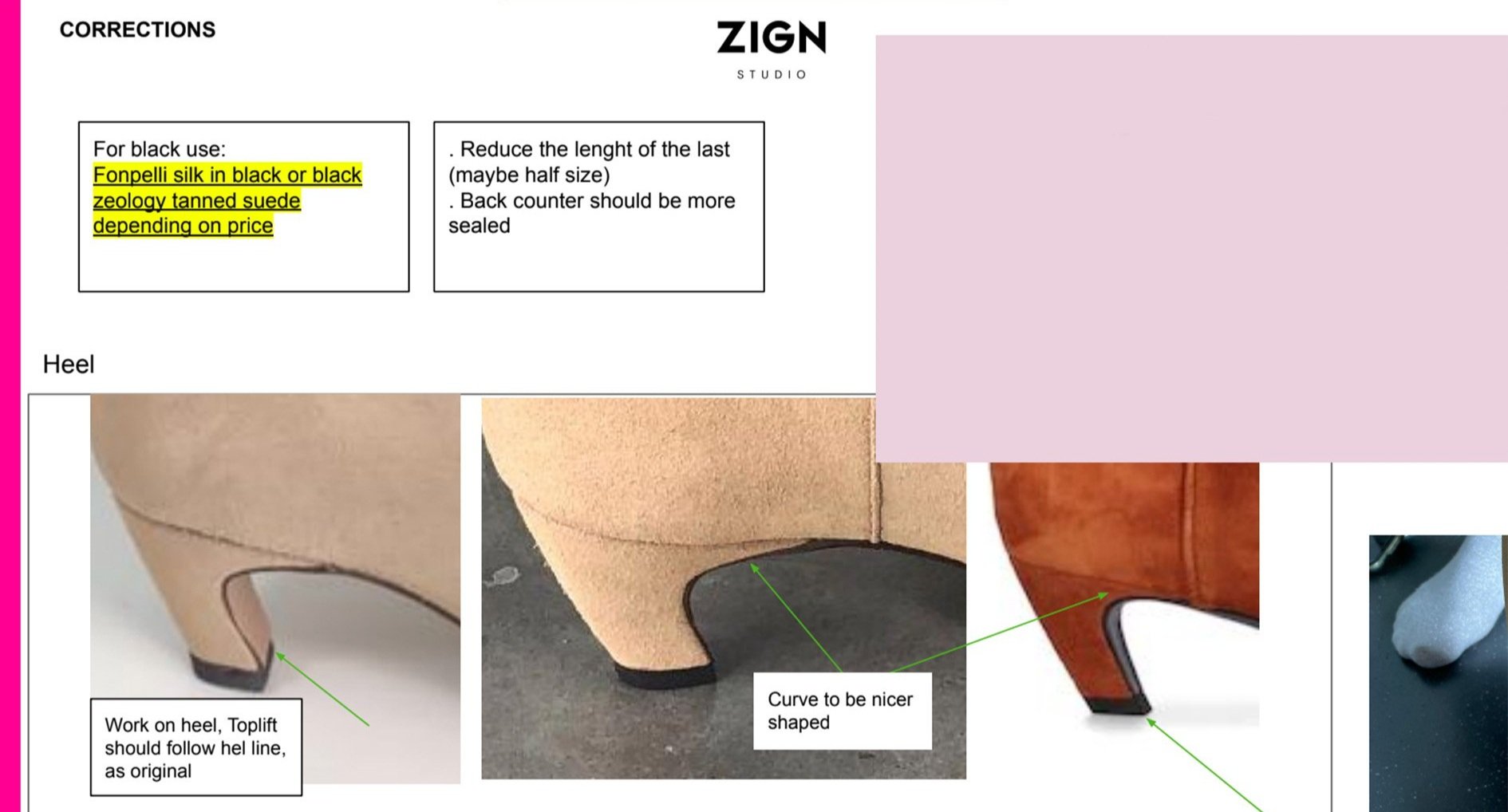

Leveraging our product design expertise, we created technical drawings and worked closely with the factories and our Materials Team to test the usability of innovative materials through sample-making.

6 . Sample Inspection

Physical sample was then send to our product development team, and together we inspect the sample for durability and finishing, if any adjustments are needed, we will passed the feedback accordingly. At this phase, we will also look at the price quotation given based on the workmanship and result of the product.

Learnings

Given our sensitive budget, there are times when the quoted prices exceed our limits. To address this, we improve the design lines to maximize leather consumption efficiency, leading to lower raw material costs.

The Result.

The Launch of ZIGN Studio

The products will be launched in A/W 23 as part of the ZALANDO DO.Better movement. While sustainability entails a journey of trial and error, as members of the private label family, we are committed to continually improving and evolving with each season.

Observation

Our challenge extends beyond the product itself. We collaborate with the marketing team to provide feedback on how to effectively present the sustainability score of the product, aligning with our commitment to transparency for our customers.

The Learnings.

Circularity is a Journey.

We learned that sustainability and circularity present unique challenges at various manufacturing stages. To create a circular product, we discovered that prioritizing quality is essential. With each product, we continuously learn and challenge ourselves to create an even better one.

Circularity starts with thoughtful Design & Material.

In the high street fashion industry, we typically build collections with fast seasonal products to drive sales. However, with circularity in mind, the Design Team has learned to slow down and thoroughly understand the properties of innovative materials. This involves determining the most suitable footwear category for each material and designing footwear that best showcases its qualities.