SPEARHEADING THE SUSTAINABLE FOOTWEAR STANDARD in E-COMMERCE

The Problem.

Despite increasing consumer demand for sustainable products, there is a lack of industry-wide standards and criteria for determining the sustainability of footwear.

This absence of clear guidelines makes it challenging for consumers to make informed decisions when purchasing shoes, leading to confusion and skepticism regarding the sustainability claims made by various brands.

As part of the ZALANDO product supply team, I work closely with the internal sustainability team to address this gap. With my product background, I wish to take a proactive approach by developing a set of comprehensive sustainability criteria for footwear manufacturing. We aim to establish clear guidelines that not only align with our own sustainability goals but also empower consumers to make more sustainable choices

To define clear and robust sustainability standards for the footwear in the High - Street Market.

Empower consumers to make more informed purchasing decisions in relation to sustainability.

Drive innovation and continuous improvement in footwear manufacturing practices, gearing towards greater environment and social responsibility

To position ZALANDO as a leader in sustainable manufacturing practices and contribute to positive industry-wide change

The Objectives.

My Role.

I collaborated closely with the central sustainability team to develop a comprehensive framework of criteria that are holistic, relevant, and vital for crafting more sustainable high street footwear. As someone focused on product development, I provide guidance and contribute to the creation of component-based criteria, ensuring a design perspective aligned with science-based sustainability principles and current EU regulations.

Additionally, I oversee the project to establish a Standard Operating Procedure (SOP) framework, ensuring equitable distribution of tasks and responsibilities among stakeholders. This is crucial for ensuring proper adherence to sustainable criteria throughout the process.

What I did.

Current Footwear sustainable landscape research

Stakeholder Engagement

Collaboration in Life Cycle Assessment

Criteria Development.

What we want to achieve.

A set of finalized component-based sustainability criteria for footwear (development and manufacturing) based on three strategies that are aligned with the Ellen MacArthur Foundation’s circular design guidelines

Guidelines for implementation and monitoring

Task guidelines for each stakeholder with a clear delegation of responsibilities and tasks

The Process.

1. Discovery

While sustainability standards are well-established in apparel, the realm of footwear, with its complexity, lacks a consistent approach among high street brands. This inspires us in private label to embark on a mission to challenge the status quo. Leveraging insights from leading brands, we aspire to pioneer a standardized criteria for sustainable footwear manufacturing.

2 . Define

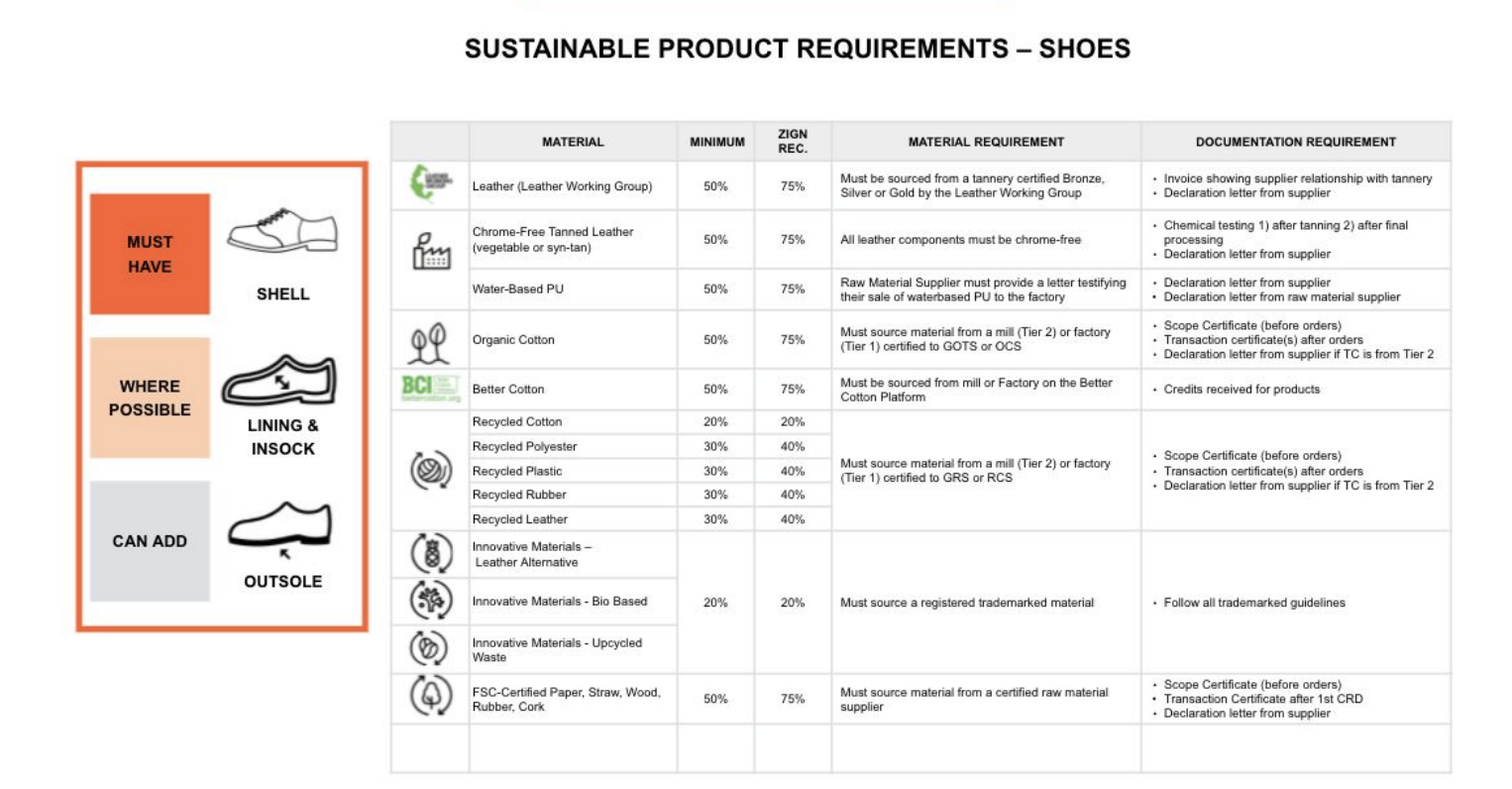

Based on the Ellen MacArthur Foundation’s circular design guidelines, which emphasize three pillars of sustainability—using renewable materials, ensuring durability, and recyclability—we focus on the first two pillars. Our criteria ensure that products are made from safe, recycled, and renewable materials and are designed to last longer, be repairable, and potentially include digital product passports to support circular business models.

Design is crucial as it sets the foundation for the product. We aim to set clear, scalable design requirements to ensure our products meet the minimum sustainability standards.

3 . Prototype

Through close collaboration with various stakeholders, including the Central Sustainability, Material, and Buying teams, we develop a component-based criteria. We also focused in incorporating well-vetted and industry-recognized certifications for each component into our criteria to ensure that our products meet the sustainability requirements.

4 . Material Alignment

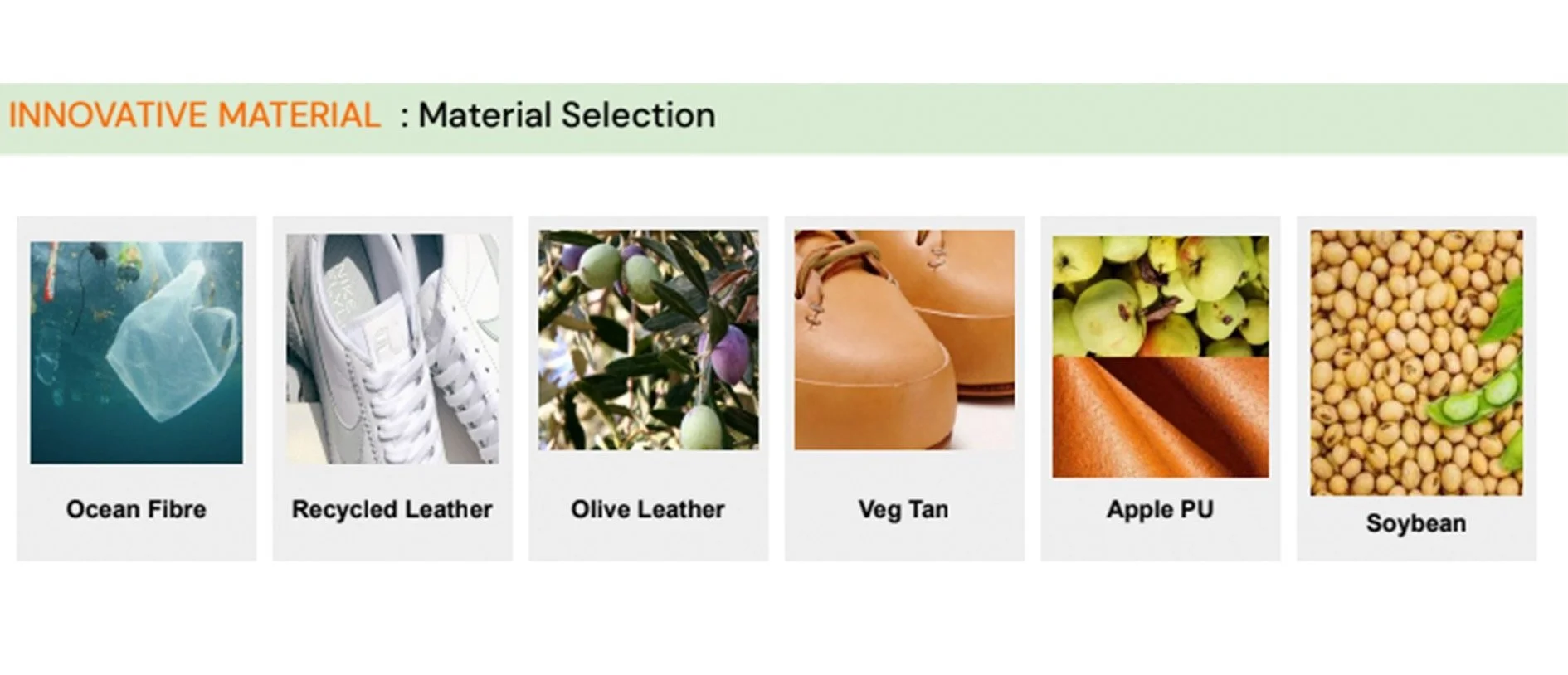

In addition to developing component-based criteria, we refined our manufacturing and material selection processes to align with these standards. By closely collaborating with the material team and our nominated factories, we optimized our sustainable and innovative materials to ensure they are suitable for footwear manufacturing within the targeted cost price.

Observation

With so many sustainable and innovative materials on the market, we've learned through trial and error which ones work best for different types of footwear. Another challenge we face is the cost of these materials. While some are beautifully made, we need to stay within budget. We embrace this challenge and are determined to find the perfect balance.

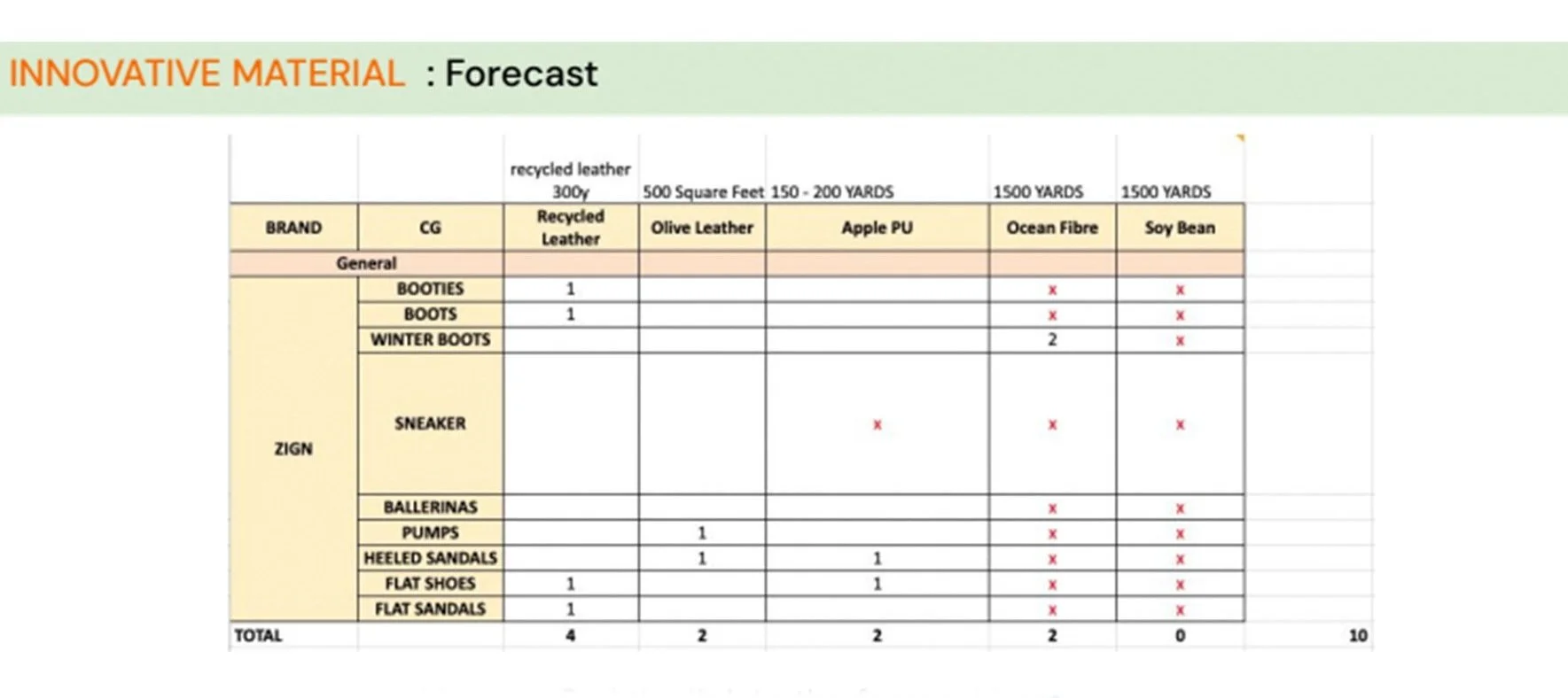

5 . Material Allocation

As part of our holistic approach to sustainability, we closely collaborate with our nominated factories and buying team to optimize material consumption. Through mindful planning, we ensure that every yard of material is used efficiently, producing the best footwear for our customers without any waste.

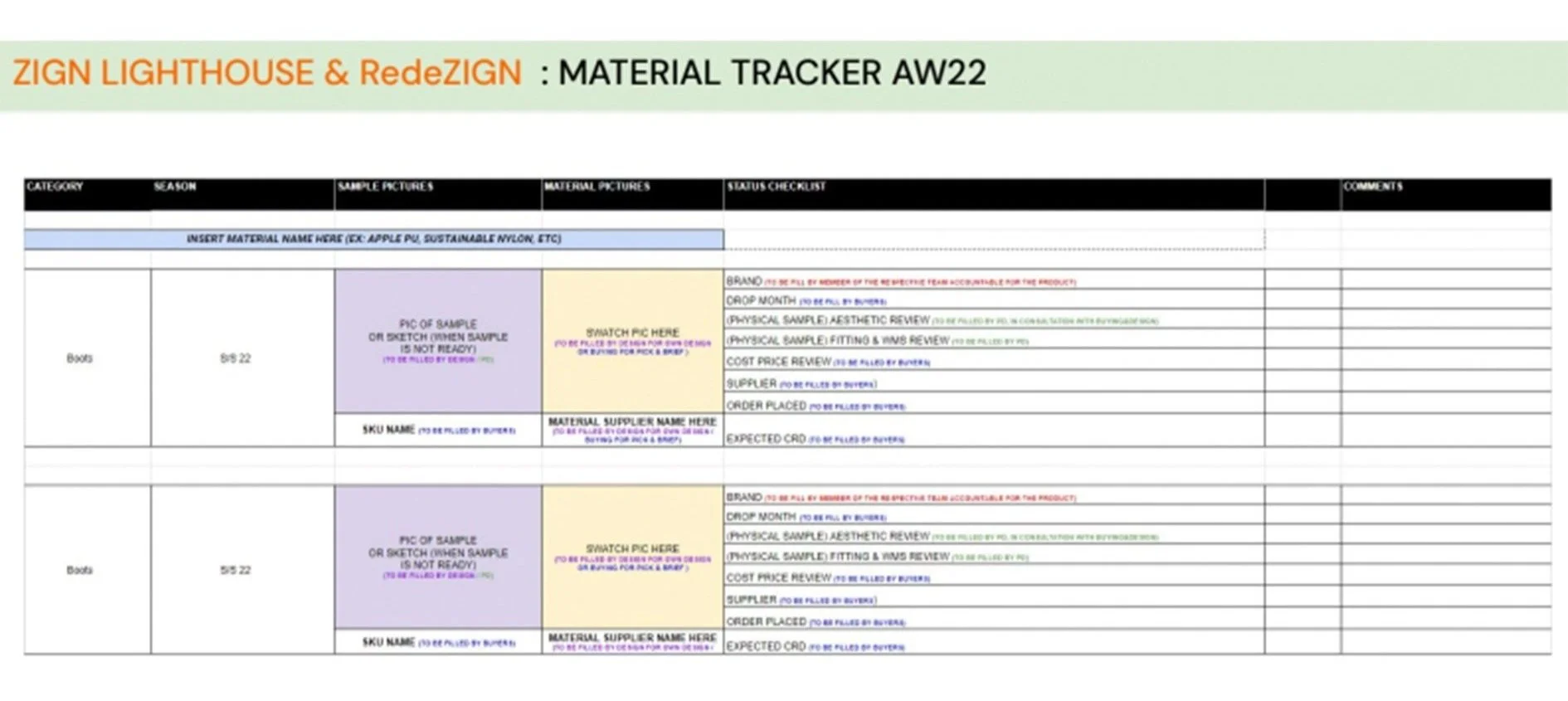

I've developed a tracking tool for stakeholders to use, providing a comprehensive overview of material consumption. This tool also helps us understand which materials are used in each footwear category and assesses the success rate of each category in terms of final product quality and cost. This valuable insight informs our planning for the next season.

Observation

Since each footwear category requires varying amounts of materials, we determine the most suitable materials for each category and collaborate closely with relevant stakeholders to minimize waste. We aim to ensure that every yard of material is utilized efficiently in production.

6 . SOP Creation

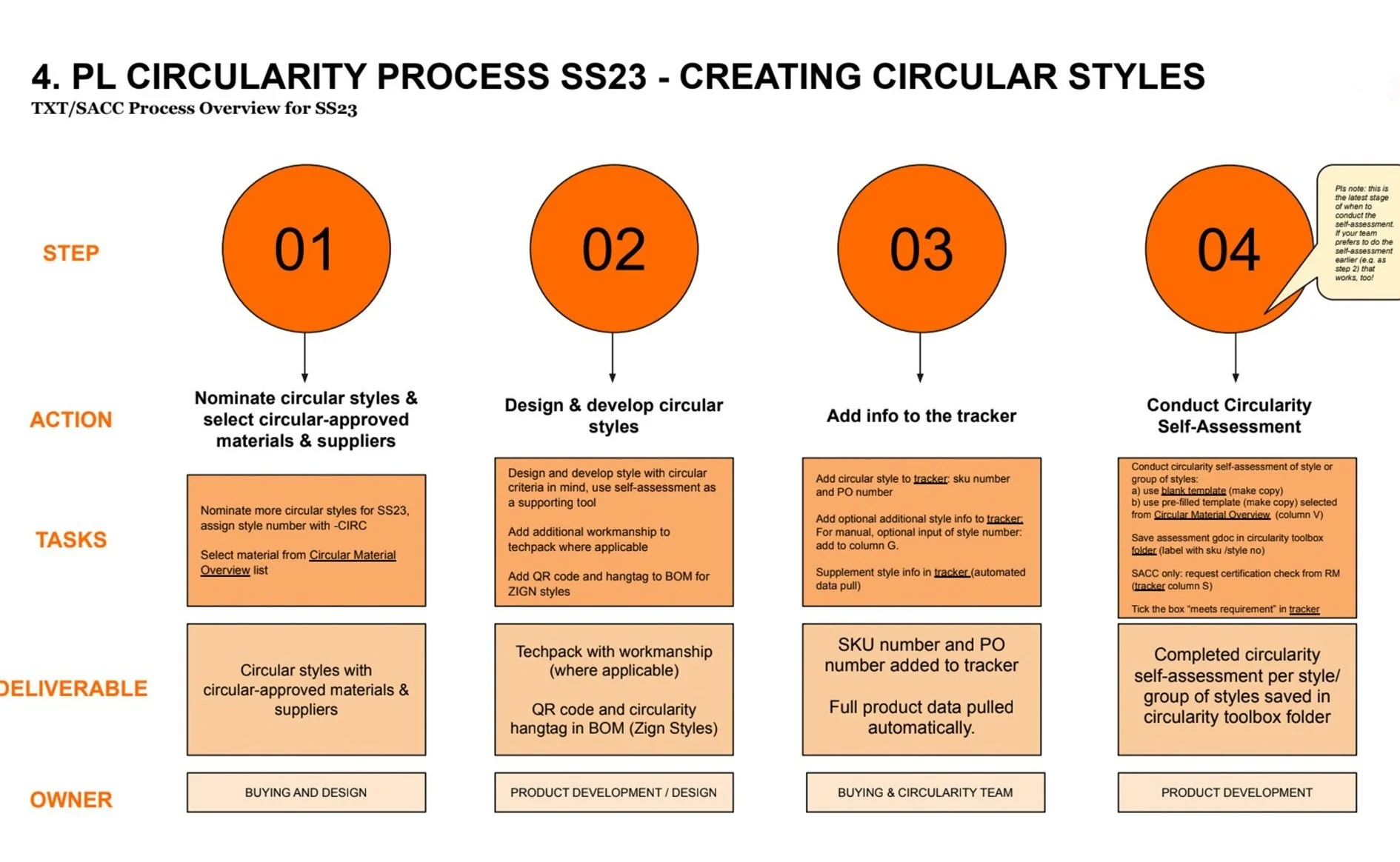

Together with the central sustainability team, I, representing the private label product team, developed a clear, simple, and efficient process, along with a self-assessment tool for each department. This ensures a balanced workload across cross-functional teams. The SOP aims to reduce the amount of manual data input required from stakeholders and to minimize their mental and manual workload.

The Result.

Test and Tune

The criteria underwent testing for the 2023 footwear collection under our exclusive private label brand “ZIGN STUDIO”, spearheaded by the design team with the support of material team and product development team. We created tech packs within the framework of the criteria, material selections and cost price.

Once the sample are received, we have a fit trial to ensure the selected materials are robust and suitable for the intended style and send them to the buying team for sign-off. .

Observation

We continuously refine the criteria, material selections, and cost price range throughout the tech pack and sampling process. With the support of our nominated factories, we gain valuable insights on optimizing production while still creating impactful footwear products. This is an ongoing learning experience for our product team, and we're always excited to improve and innovate.

The Learnings.

While no footwear products are 100% sustainable yet, mindful design can help us create products with a more positive impact.

Although sustainability has made significant strides in other fashion categories like apparel, footwear remains more complex. We're limited by the sustainable progress of each component available in the market. We embrace a test-and-trial approach, learning from each experience and applying those lessons to our next season's collection.

Creating sustainable products requires mindful collaboration between stakeholders.

Although sustainability has made significant strides in other fashion categories like apparel, footwear remains more complex. The sustainable progress of each component available in the market limits us. We embrace a test-and-trial approach, learning from each experience and applying those lessons to our next season's collection.